Single stone smoothing diamonds still hold a very important place in the grinding process. It is an undeniable fact that single stone smoothing diamonds have versatile areas of use, depending on the selected abrasive wheel. In many applications, the most suitable tool is a correctly selected high-quality single stone smoothing diamond.

Choosing the right diamond is a job that requires a lot of experience. Diamonds are carefully selected according to their shape, structure, usable corners, cracks and stains and are put together as a set.

How to Use:

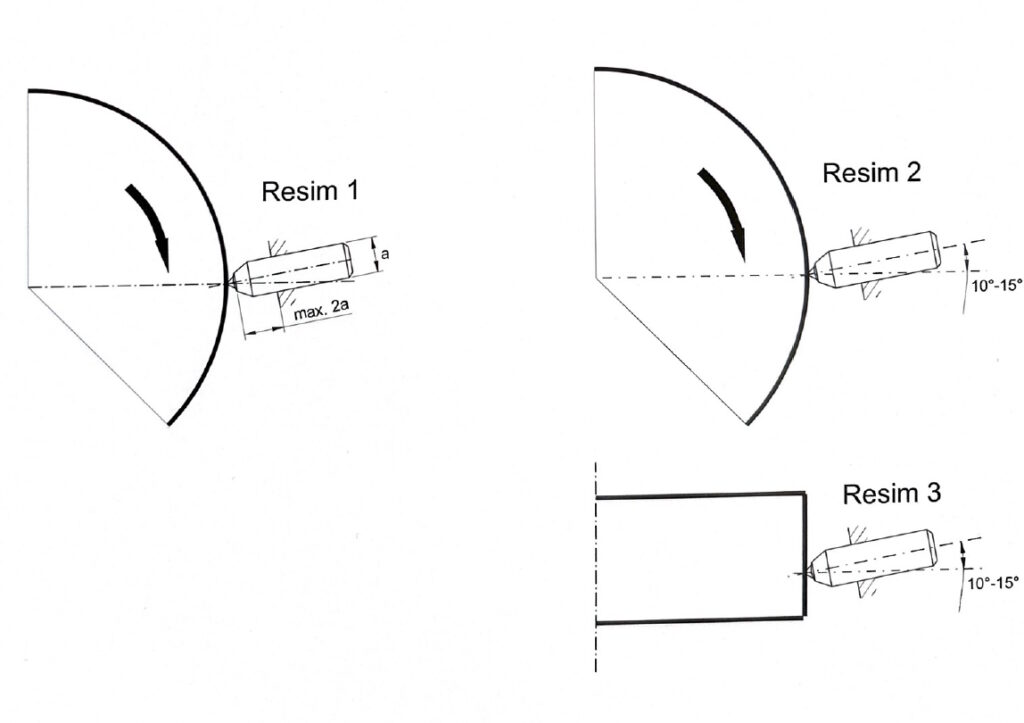

Single stone correction diamonds should be attached to the bench at the angles shown in Picture 2 and Picture 3 below.

As in Picture 1, the distance between the tip of the diamond and the place where it is attached to the sleeve should not exceed 2 times the shank diameter.

Sharpening passes should be less than 0.03 mm.

Repair/Corner Replacement of Single Diamonds

Corner replacement of single diamonds should be done when a wear surface of more than 1mm2 is formed on the diamond tip. As shown in the figure below, wear down to the iron part makes corner replacement difficult or impossible. Using the diamond while its tip is sharp is the most economical way of use.